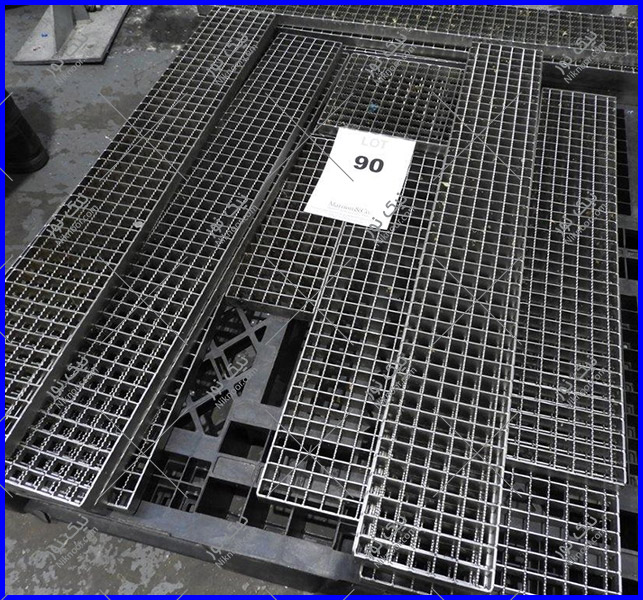

Grating

Grating is a metallic, mesh-shaped structure with applications including load-bearing, emergency stairs, areas with gas accumulation risks, water drainage channels, factories, and more. Grating comes in two types: metallic and non-metallic, with the metallic model being specially manufactured at Niknoor. Additionally, hot-dip galvanizing or painting is used for coating the grating for aesthetic purposes.

Components of Grating:

- Carrier Bar: The strength, load-bearing capacity, and tension of the grating depend entirely on this part, the carrier bar. This component may vary based on the customer’s requirements and installation location.

- Mesh or Spacing: The distance between the carrier bars and connectors is referred to as mesh or spacing. The smaller the distance, the denser it is, and consequently, the strength increases. The mesh also significantly impacts the weight and resistance of the grating.

- Support: The bars are kept in place by the support, which only affects the appearance of the grating and does not influence its load-bearing capacity like the connectors do.

- Connector: Connectors are used to maintain the shape or appearance of the grating. The connector is attached vertically to the bars and does not bear weight. Therefore, the distance between the connectors does not affect the strength of the grating, but it does influence the ease of movement. For instance, in high-traffic or sensitive areas like emergency stairs, the distance between connectors is reduced to prevent shoe heels from getting stuck between them.

Share this page