Explosion-Proof Equipment

Due to the presence of explosive gases and dust in certain industrial facilities such as oil, gas, petrochemical, pharmaceutical, paint manufacturing, cement factories, chemical industries, automotive manufacturing, fuel stations, silos, mines, etc., the use of electrical equipment can cause severe and irreversible hazards. To prevent such accidents, installations and devices that are installed in explosion-prone areas must be designed, manufactured, and installed in a way that ensures necessary protective measures against electric shock, sparks, inductive failure phenomena, etc., in both normal operation and when faults occur. Such equipment is referred to as explosion-proof equipment.

Electrical devices and equipment used in hydrocarbon facilities, considering the risk of explosion and fire, must have a completely isolated body from the surrounding environment to prevent fire or explosion. In the event of an explosion inside them due to gas, they must be capable of withstanding the pressure from the explosion and preventing the spread of flames to the surrounding area.

The failure to use explosion-proof equipment, due to negligence regarding safety conditions, has repeatedly led to irreversible incidents in industries, including explosions in mines and refineries and fires in spinning and weaving factories due to the presence of flammable dust.

To correctly select explosion-proof electrical equipment, two factors must be considered. First, identifying hazardous industrial areas and assessing the level of risk within them, which will depend on the presence of combustible materials, the likelihood of their release, and the quantity and type of these materials in the operational space. Second, selecting devices and equipment from available industrial types whose bodies are suitable for installation in the aforementioned classified and identified spaces.

Explosion-proof electrical equipment is divided into two main groups:

- Group I: Electrical equipment for mines

- Group II: Electrical equipment for other hazardous areas

Group II electrical equipment is further subdivided into IIC, IIB, and IIA groups. This classification depends on the level of risk associated with gases and dust. Group IIC equipment is suitable for use in most hazardous explosive atmospheres and can cover IIA and IIB gas groups. Additionally, Group IIB equipment can cover IIA group, but the reverse is not possible.

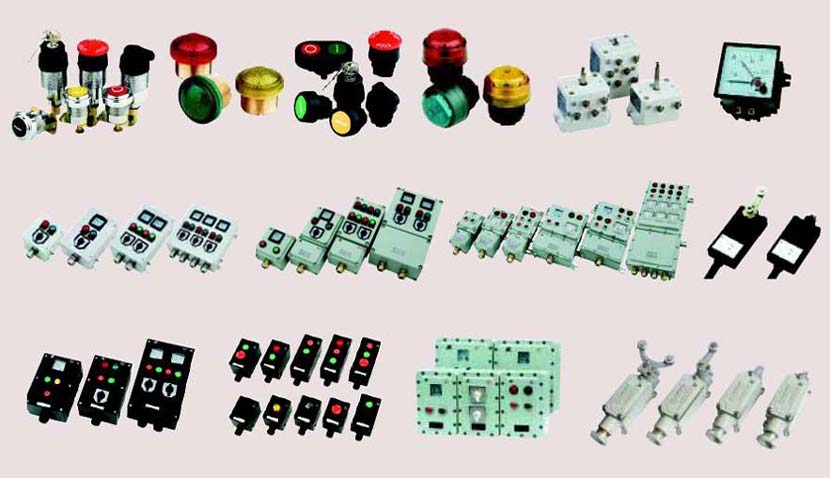

Types of Explosion-Proof Equipment

Explosion-proof products have a wide range, including the following:

- Types of explosion-proof lighting (fluorescent, workshop lights, projectors, hand lamps, warning lights, etc.)

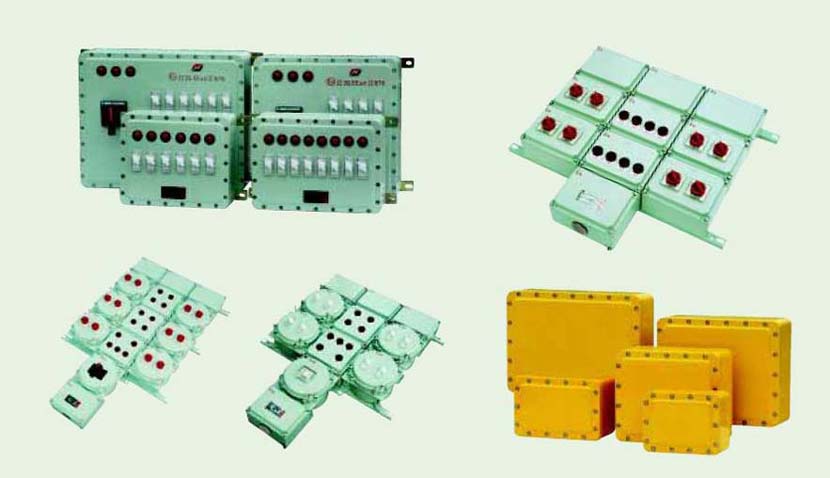

- Explosion-proof enclosures and terminal boxes

- Explosion-proof switches, sockets, and plugs

- Explosion-proof electrical panels and control stations

- Explosion-proof switch gears

- Explosion-proof coolers

- Types of explosion-proof glands and fittings

Share this page