Lighting Tower

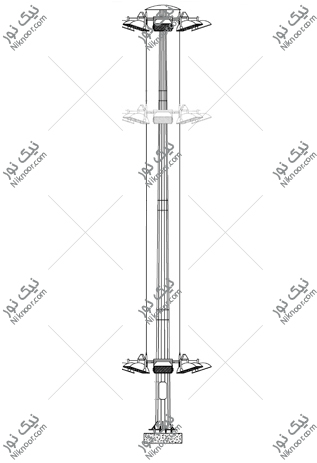

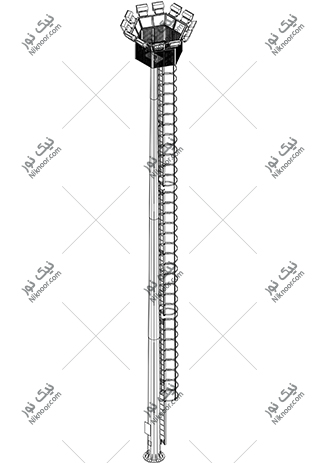

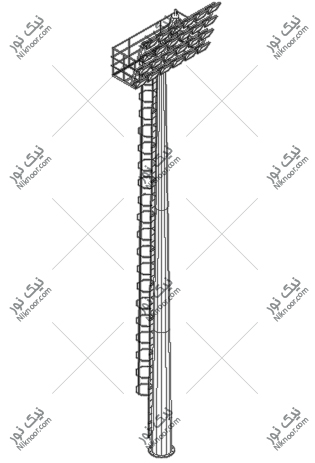

The lighting pole, also known by other names such as illumination tower, lighting mast, or lighting tower, is a metallic structure equipped with several floodlights used to provide lighting for large areas. Generally, the lighting tower consists of two main parts: the main column and the projector frame or basket, which is the area where the projectors are mounted.

Types of Lighting Towers

Lighting towers are manufactured in three models: movable, fixed, and stadium. It is worth noting that stadium lighting towers are technically a subset of the other two models, but due to their extensive use in the market, they have been categorized separately.

Fixed lighting towers come in two types: with or without ladders. Movable lighting towers are also available in two variations: manual and motorized. Each of these products has been fully detailed in their respective categories. At the top of lighting towers, a lightning rod can also be installed if needed.

Additionally, a small comparison of these three models has been provided below. (Click the button below to view it.)

Coating of Lighting Towers

To protect against rust or corrosion, lighting towers are usually coated using two methods: 1. Hot-dip Galvanized Coating, 2. Industrial Paint Coating. When selecting either of these coatings, the following parameters should be considered:

- The climatic conditions of the installation area in terms of humidity

- The architectural characteristics of the installation site

- Cost

Important Note:

Due to the heavy weight of the lighting tower, a crane must be used for loading. If the coating is paint, this process could damage the coating. Therefore, it is strongly recommended to use a galvanized coating for lighting towers.

Why Choose Niknoor Lighting Towers?

Experience and Expertise: Niknoor Lighting Industries, with 28 years of experience in manufacturing various types of lighting masts, has consistently produced high-quality lighting towers using state-of-the-art machinery and cutting-edge technology.

Direct Manufacturer: Niknoor is a direct manufacturer, eliminating intermediaries to deliver lighting towers directly to you, the valued consumer. All stages of production, from start to finish, are carried out by skilled and experienced experts within the company.

Fully Customizable Production: With its talented and creative team, Niknoor can produce completely customized products, turning any idea you envision into reality.

Comprehensive Transport, Installation, and Execution Services: Your collaboration with Niknoor doesn’t end with project completion. The company handles all installation and execution stages based on your request or dispatches experts to ensure proper installation oversight.

Warranty: Niknoor provides a 24-month warranty for all its lighting towers.

Production Monitoring: A key feature that fosters trust between Niknoor and its customers is the opportunity for clients to directly oversee every step of the manufacturing process, even at the company’s factory.

Fast Production: Understanding the importance of time, Niknoor is proud to deliver lighting towers in the shortest possible time without compromising quality.

Lighting Tower Pricing

Several factors influence the pricing of lighting towers, including:

Height of the Lighting Tower:

the taller the tower, the more steel is used, which increases the overall cost of the structure.

Type of Lighting Tower (Movable or Fixed):

Movable lighting towers are generally more expensive than fixed ones due to their larger body diameter, needed to accommodate the gearbox. Additionally, accessories like ladders, baskets, guards, motors, and gearboxes directly affect the price.

Type and Number of Floodlights:

The type, power, and number of floodlights significantly impact the structure’s cost.

Projector Arrangement (Symmetrical or Stadium):

Fixed and movable towers with symmetrical arrangements are more balanced against wind. In contrast, stadium towers require stronger, more precise bases due to the asymmetrical arrangement of floodlights, increasing the cost.

Coating Type:

As previously explained, the choice between hot-dip galvanization or industrial paint affects the price.

Diameter of the Main Column:

A larger column diameter indicates more steel usage, leading to a heavier and costlier structure.

Thickness of Sheets Used:

The thicker the sheets used in the base, the heavier the structure and, consequently, the higher the cost.

Order Quantity:

Niknoor offers special discounts for partners placing orders above a specified quantity threshold.

You can contact Niknoor’s experts to receive any technical consultation and get the latest pricing details for various types of lighting towers.

Types of Lighting Towers

Applications

Providing dispersed lighting for large areas

Suitable for Use in:

- Open parking lots

- Factories

- Parks and recreational areas

- Docks, ports, and airports

- Large urban squares

- Oil, gas, and petrochemical sites

Coating

Hot-dip galvanization or industrial paint

Assembly

Overlapping (Overlap method)

Applications

Providing dispersed lighting for large areas

Suitable for Use in:

- Open parking lots

- Factories

- Parks and recreational areas

- Docks, ports, and airports

- Large urban squares

- Oil, gas, and petrochemical sites

Coating

Hot-dip galvanization or industrial paint

Assembly

Flanged or overlapping (Overlap method)

Applications

Providing concentrated lighting in a specific direction

Suitable for Use in:

- Stadiums

- Sports fields

- Refineries

- Factories

- Arenas

- Loading docks

Coating

Hot-dip galvanization or industrial paint

Assembly

Flanged or overlapping (Overlap method

Completed Projects by Niknoor Company

Share this page