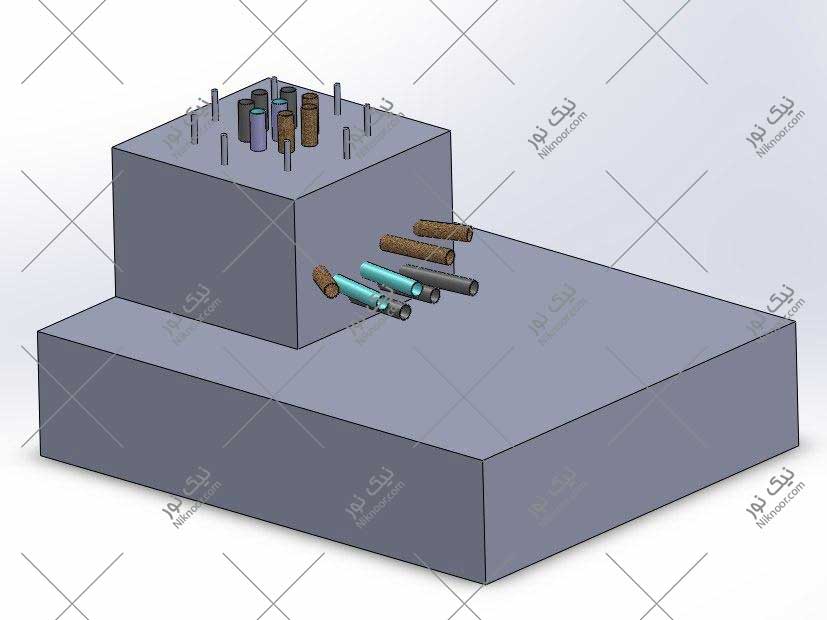

Precast Foundation

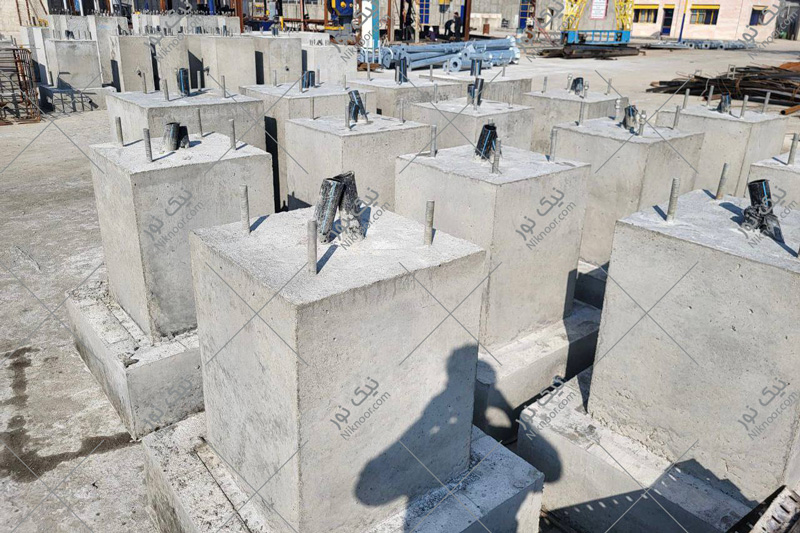

A precast foundation is a product made by casting concrete into a mold or reusable form, which is then transported to the construction site and placed at the project location. Producing precast concrete in a controlled environment provides an opportunity for proper curing and close monitoring by factory personnel. Using a precast concrete system offers many potential advantages across the concrete casting site. The production process for precast concrete is carried out at ground level, contributing to project safety.

Precast Foundation Construction

In precast concrete foundation construction, compared to mixing concrete on-site, there is greater control over the quality of materials and workmanship in a precast factory. From a financial perspective, the molds used in a precast factory may be used hundreds to thousands of times before needing replacement. This reduces the cost of mold work per unit in precast factories compared to on-site concrete construction.

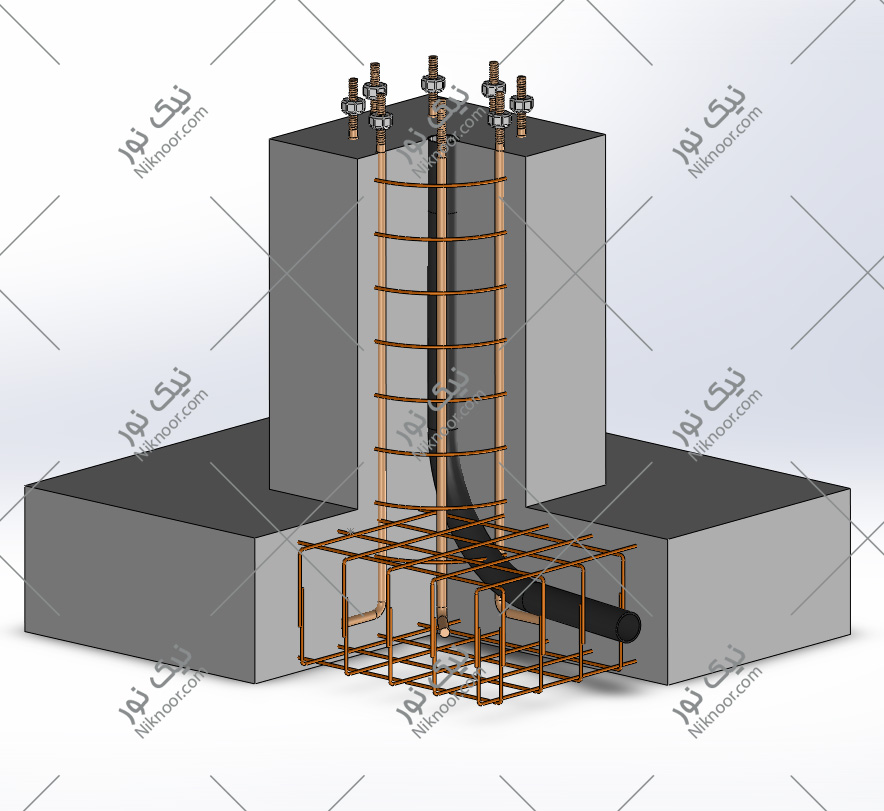

Due to the production of parts in a factory, the quality of the parts is higher than those produced in workshops, and the construction time is faster than traditional systems. The traditional construction method for reinforced concrete involves steps such as excavation, precast foundation installation, formwork, and pouring concrete, each of which requires a considerable amount of time depending on various factors. By using this technology, it is possible to reduce labor, shorten construction time, and increase accuracy and quality in precast foundation industries. Another product commonly used alongside foundations is anchor bolts.

Work is done in a controlled environment where tools, workspace, and construction sequences are pre-determined. This feature increases safety and operational efficiency on the project site. The production and construction area for precast foundations is often covered and enclosed, enabling work to be carried out in any weather conditions, thus avoiding delays caused by adverse weather. It also saves time in the assembly of parts at the installation site.

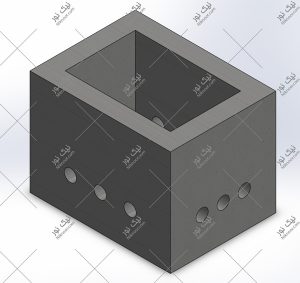

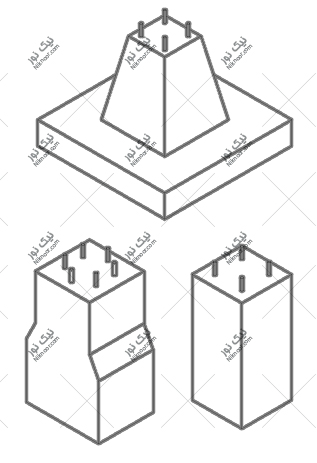

Precast Foundation Drawing

Advantages of Precast Foundations

Modern methods cover the weaknesses of traditional methods to a great extent. Some of the advantages of precast foundations and light pole foundations include:

- Optimal use of materials and, in some cases, the possibility of recycling materials

- Increased speed and reduction of unnecessary finishing work

- High-quality control

- Greater safety

- Energy savings

- Reduced manpower

- Better resistance

Price of Precast Foundation

Towers and poles are typically used in open environments, and natural factors such as wind, snow, earthquakes, etc., can cause them to collapse. Therefore, precast foundations and light pole foundations must be built to secure the tower or pole against various conditions. As a result, their quality is very important. If we want to list the factors that affect the price of precast concrete foundations, we can mention dimensions, concrete grade, diameter and density of concrete reinforcement, and the number and size of anchor bolts.

Light Pole Foundation

To install a light pole, you need a light pole foundation. The best option for these poles is to use precast concrete foundations, which are both cost-effective and time-efficient. It should be noted that the materials used for constructing the light pole foundation at Niknoor Company are in line with globally defined standards and are specifically designed for these poles.

Related Topics

Share this page